Highlights

- From a tonne of stubble, 500 kg of pulp can be produced

- Pulp can then be used for making products like paper, cups and tableware

- Farmers can also sale the pulp for Rs 40-45 per kg to generate revenue

New Delhi: The seasonal burning of crop residues, especially paddy straw, by farmers of Punjab and Haryana contribute significantly to the national capital’s air pollution woes, with severe consequences for public health. In the wake of air pollution crisis in Delhi NCR during the last winter, both central and state governments have come up with a number of awareness activities and subsidies to encourage farmers to stop stubble burning and adopt alternative straw management strategies. Understanding that the farmers, devoid of cost-effective alternatives, end up burning the straw, the graduates of Indian Institute of Technology (IIT) – Delhi, have developed a processing technology to convert agro-waste like paddy straw into pulp – which can then be used to make several biodegradable products like paper, plates, cups and other tableware, thus generating revenues to incentivise farmers to not burn the straw.

Also Read: Stubble Burning In Punjab: The Government Issues Directions For Combine Harvesters

Kriya Labs, a startup incubated at Technology Business Incubator at IIT Delhi, developed this processing technology, which is unlike the existing pulp-making process that requires heavy machinery and economIES of large scale.

Speaking to NDTV about the process, Mr Ankur Kumar, Co-Founder and CEO, Kriya Labs said, “Our process can be economically integrated and sustainably run even in smaller scales. Additionally, the solvent system developed for the process is also completely biodegradable, non-volatile, made of natural products and completely safe to use. With our process, we add value to the agro waste near to its generation site by facilitating setting up small scale pulp-production units in a decentralised system.”

How this processing technology works:

Paddy straw composes of high silica content that animals are not able to digest, while the farmers properly manage the wheat straw as that is widely used as animal fodder. Since sufficient wheat straw is available, there is limited demand for paddy straw. So, the farmer under the pressure of clearing fields quickly for the next season burns the stubble.

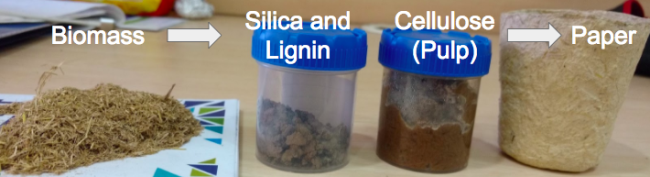

“We have developed a process to segregate the silica and lignin (organic polymer) of the rice straw from the usable cellulose (pulp). The process to create pulp uses natural biodegradable chemicals. The pulp is dried and moulded into various shapes (cups, plates etc) with the help of machines. The process can be performed economically at lower scales of processing 1-2 tonnes of straw per day also, sufficient for at least 200 acres of crop residue. From one tonne of stubble, 500 kg of pulp can be produced, which can then be sold for Rs 40-45 per kg, even by the most conservative estimate. This helps the farmers generate revenue of Rs. 2-3 against a kilogram of straw.” said Mr Kumar.

The CEO of Kriya Labs further explains that the pulp produced has various applications in the paper based industries for making products like sheets, cups and other tableware. It can also be used as raw material for production of foams and furniture items.

“Our process can be integrated in small scale machines for multiple decentralised cluster production. It costs around Rs. 30-35 lakh to setup a processing unit that can process two tonnes of straw per day,” Mr Kumar further added.

Also Read: Australia Offers Technological Help To Prevent Stubble Burning

While speaking to NDTV about the economic viability of this technology, Dr. Neetu Singh, Asst. Professor, Center for Biomedical Engineering, IIT Delhi, said “The development of this technology has been artistic. It beautifully integrates science with the society, environment and economics. The process has been developed in a manner such that it can be executed by assembling existing machineries. Thereby, exponentially decreasing the transition time from a lab to field. Besides, it has to be seen as a bio-refining process than a pulp-making process. The by-products generated can be utilised to develop another chain of value added products, adding another layer of economic viability. The team consists of young graduates coming from different expertise, thus making it more vibrant, enthusiastic and culturally rich.”

Also Read: Stubble Burning: An Inside Look Into The Popular Practice For Punjab’s Farmers

According to the developers of this technology, IIT-Delhi graduates who left their lucrative jobs to find a sustainable solution to stubble burning, this technology will empower rural India by connecting agriculture and manufacturing, as a result of which the farmers will start taking agricultural waste as an asset.

himaja

May 21, 2018 at 3:31 pm

can u please explain breifly,how this processing technology works.

D.sudhakar

August 1, 2018 at 12:23 pm

can u explain the processing technology

Maddula nagendra

May 14, 2020 at 10:28 pm

Can you explain eloborately?

Trish Garg

June 6, 2020 at 3:46 pm

Can you please explain the process summary to separate Pulp and Lignin/Silica and how much land is required for the same.

Faizan

September 13, 2020 at 10:53 pm

Mujhe Janna Hai Sara process kya kya machine lagega kya rate hai uska Kaise kam Karega market Mein Kaise advertise Karen

Rajesh Chamua

November 16, 2020 at 12:11 pm

Please provide me the knowledge which u mentioned above. I wish to experience the practical and to start the business.

ASIM KUMAR KATIYAR

February 13, 2021 at 10:55 pm

I want to know whole process of production of pulp from paddy straw because I want to establish this project in my Kanpur city. Please give me full techonology with full project report .

Thanks.

Dr. P. . Hari prasada rao

October 25, 2020 at 7:29 pm

Very interesting it prevent harmful carbon gases in environment

Deepak pednekar

February 9, 2021 at 9:18 pm

pls give details, so people like us will approach farmers for this and in turn they might not burn

alka sharma

March 17, 2021 at 11:33 am

i would like to know about this process and the total investment…..

Mahendiran

December 13, 2022 at 8:07 am

want to know whole process of production of pulp from paddy straw because I want to establish this project in my Kanpur city. Please give me full techonology with full project report .

Thanks.